Using a photopolymer emulsion (compared to a diazo-based emulsion) when you have a low UV light source will make a huge difference toward success or failure when making a stencil. Photopolymer liquid emulsions (and photopolymer capillary film) work well even with poor light sources. Manufacturers developed photopolymer emulsion products because they know that many screen printers use an exposure light source that is less than ideal. It exposes very quickly and has a wide exposure time range. Photopolymer emulsion is very sensitive to light. If you think of emulsion (or capillary film) as the “photographic film” used to make your stencil, think in terms of speed and light sensitivity. While the light source will determine what kind of art you can use to make a stencil, the type of emulsion or capillary film that you use is actually more important.

#LINCOLN EXPOSURE UNIT HOW TO#

If you are interested in learning more about exposure units and the screen printing process, check out Exposure Exhaustion: What Went Wrong and Screen Making 101: How to Make a Screen for Screen Printing.Most people who want to build their own exposure unit mistakenly think that the light source is the most important consideration.

#LINCOLN EXPOSURE UNIT FULL#

It offers full LPI control, the ability to choose your desired dot shape, as well as the angle of the dot to mitigate moire patterns. The Xitron/Harlequin RIP system enables custom workflows that can be created specifically for a shop to cover CMYK, Simulated Process, Spot Colors, and more. If you don’t want to worry about glass while exposing your screens, you can always go glassless with a computer to screen wax ink printer. The Douthitt CTS output is maximized with the Xitron/Harlequin RIP. You will want to be more particular about cleaning the clear class than cleaning the low iron glass.

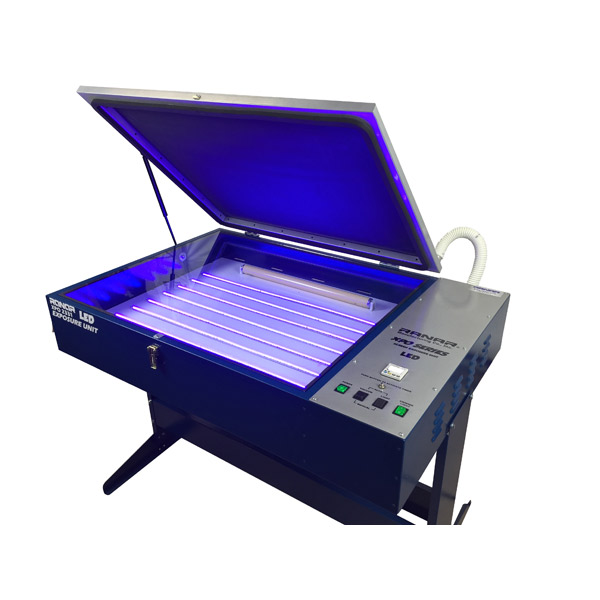

This has a little more iron it so it does block the UV rays a little bit more than the low iron glass. The more entry level units below these, like the X1620 LED Exposure Unit, include clear glass. The feature rich, pro-level higher end units, like the Y3942CTS LED Exposure Unit, include the low iron glass which produces the highest level of clarity. Ryonet offers exposure units that have either low iron glass or clear glass. Its special formula works great for cleaning both the glass of your exposure, as well as any other glass nearby. Optimized for best performance, Sprayway glass cleaner uses perfume-grade alcohol. Its heavy duty foam clings to the vertical surfaces of your exposure unit, and it is guaranteed to leave no film. Sprayway Glass Cleaner dissolves & loosens dirt, grease, grime, and grit. Don’t forget to inspect the glass before each exposure job, it is well worth it. Make sure to fully clean the glass of your exposure unit at least once a week. Using SprayWay Glass Cleaner will remove any of the spots on your glass that will cause these problems. The pinholes end up messing with your image overlapping. Bummer right?! These types of pinholes get extremely tricky during high detailed prints, especially in halftones. This will allow the ink to go through the hole during the screen printing process and create a spot of ink on your shirt that you did not originally plan for. The soft spot in the emulsion ends up washing off leaving a pinhole on the screen. Those black fluorescent tubes are usually available to purchase in many. After examining the market, I decided to construct this unit using black fluorescent tubes. I decided to build a UV exposure unit to assist my screen-printing and PCB prototyping needs. This creates a pinhole in the emulsion, meaning that there will be a spot where the emulsion did not harden. UV exposure unit is a vital component in printing and mass-manufacturing industries. Having any sort of dirty spot on the glass will block the UV rays from reaching the emulsion. It is extremely important to keep the glass on your exposure unit clean of any debris, smudges, or marks. Why You Should Clean the Glass on Your Exposure Unit SprayWay Glass Cleaner is an easy and fast way to get your glass clear and ready to expose your screens.

#LINCOLN EXPOSURE UNIT FREE#

One of the most important things you can do while maintaining your exposure units is to keep the glass on the exposure unit clean and free of debris.

0 kommentar(er)

0 kommentar(er)